SPACESHIP 60 BUILD: Brushing up on paint

- Nic de Mey

- Jul 3, 2023

- 3 min read

Updated: Oct 6, 2023

Boat painting is far from a walk in the park; it's a dusty, odorous, and physically demanding endeavour. It demands acute attention to detail, consumes a significant chunk of the budget in terms of labour hours, and is fraught with potential hazards; however, it is incredibly rewarding, and for most, it's the first thing that catches the eye when stepping onto a boat. In short, fairing and painting boats is not a pursuit for the faint-hearted.

I've developed a personal philosophy when it comes to boat painting, and I find myself sharing it with our young team members regularly: if you find sanding boats boring, you're likely not doing it right. This craft requires ample skill and unwavering patience. Our head painter, Adrian, is a true master of his trade—organized, skilled, and perhaps most importantly, an adept leader of paint teams. He's unquestionably the best I've had the privilege of working with.

The world of boat paint is in a constant state of evolution. Innovations like highly effective spray fillers and primers have significantly reduced labour and simplified the process.

Advances in sandpaper technology have made a monumental difference in efficiently painting large vessels, the one thing that hasn't changed is you still need to attach it to what the boys affectionately refer to as torture boards.

Painting advanced composite boats comes with its own set of technical challenges. Dark colours, for instance, can pose a host of issues for composites, including core out-gassing, fibre movement, and print-through. We collaborate closely with boat owners from the project's inception to understand their colour preferences. Educating clients about the potential pitfalls of dark or metallic hues can be a diplomatic exercise in explaining cost increases and associated risks. We also can have some clients not that fussed about the paint, with one asking for a 40-foot paint job when I asked what that meant .... "stand back forty feet, if it looks good, I'm happy ...... I did it, and he was, but never again, though

Identifying the likely colour of the boat from the outset helps us select the appropriate cores, fibres, and heat-resistant resins and fillers, once we have that colour information, we create test panels to mimic specific parts of the boat that are likely to be affected. These test panels replicate the exact layup of the boat's sections and undergo the entire paint process. We even resort to straightforward testing, such as placing a panel on my north-facing deck at home and monitoring its behaviour over a few hot, sunny days, nothing overly technical and usually observed with a cold beer in my hand.

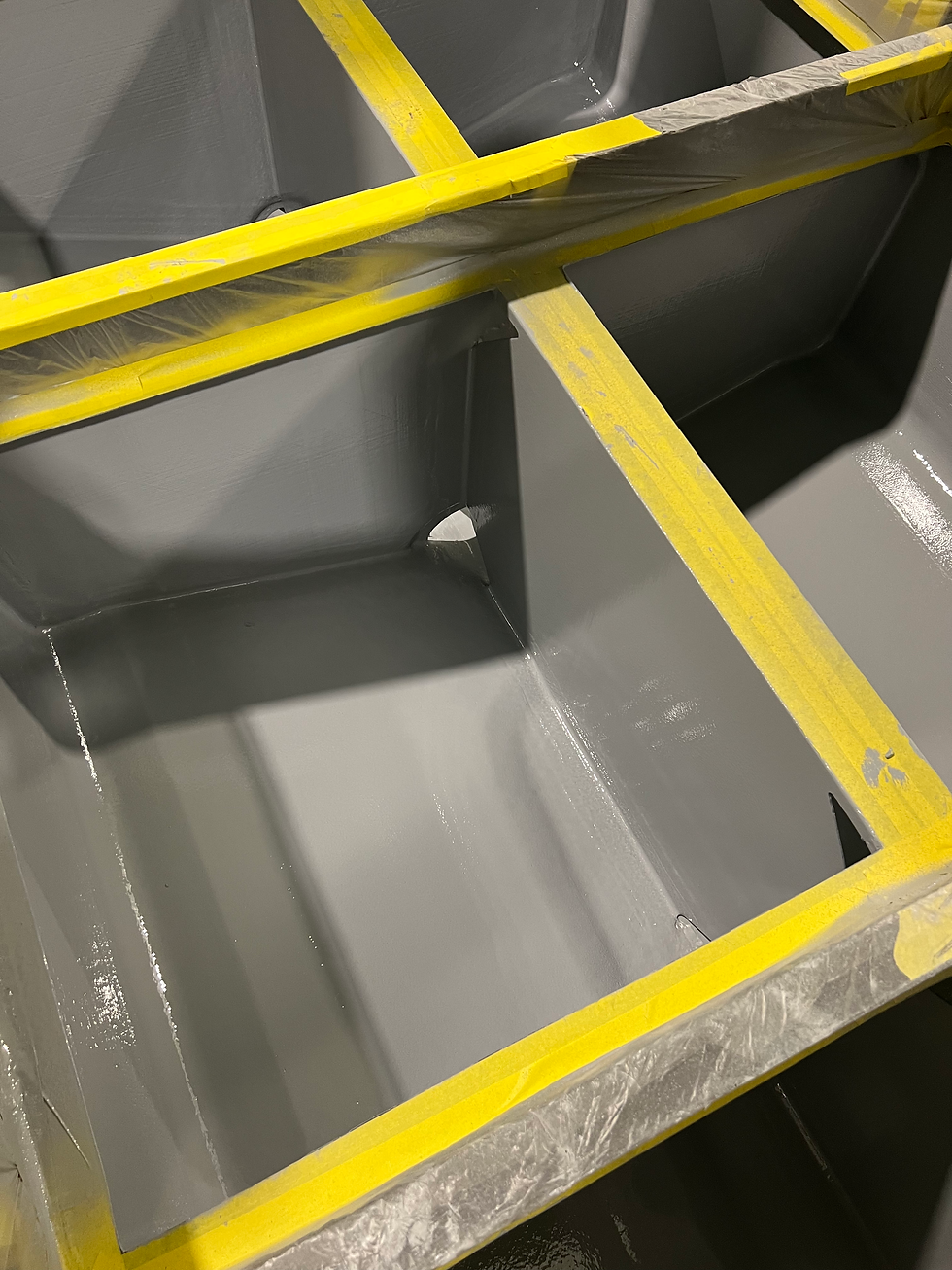

For technical paints like fuel tank coatings, thorough research is paramount. Some countries add ethanol to both diesel and petrol. Since our boats feature composite fuel tanks (where the boat itself serves as the fuel tank), it's crucial to protect the composite material from the potentially corrosive effects of fuel. We've heard (and seen) boats deteriorating due to the fuel they stored.

Utilizing dew sensors before commencing painting, strictly following technical data and QC sheets, and making use of premium equipment are pivotal steps in mitigating potential issues and attaining a top-notch paint finish. Equally essential is actively seeking feedback from the guys working with the product to enhance the overall process over time.

Fuel tanks require diligence and meticulous preparation and application.

Engine rooms are painted to an exceptionally high standard. This meticulous approach is essential as these spaces require effortless cleaning and maintenance. Additionally, the engine room often serves as a showcase where clients take pride in highlighting the uniqueness and excellence of their boat.

The worst part of painting BIG Catamarans is who gets the short straw to sand the tunnel.

Our company has a legacy rooted in the construction of race boats. Our approach couldn't be further from applying excessive filler to the boat's surface. Instead, we strive for a minimal layer, typically a few millimetres at most, with instances of sand-throughs revealing the composite in certain areas.

A pair of SPACESHIP 60 hulls fresh out of the mold before being joined to the Wingdeck, easier to paint upside down than right way up

The boys sanding the sides of a SPACESHIP 60 with "torture" boards

Test panels are critical to check a wide range of potential issues.

Comments